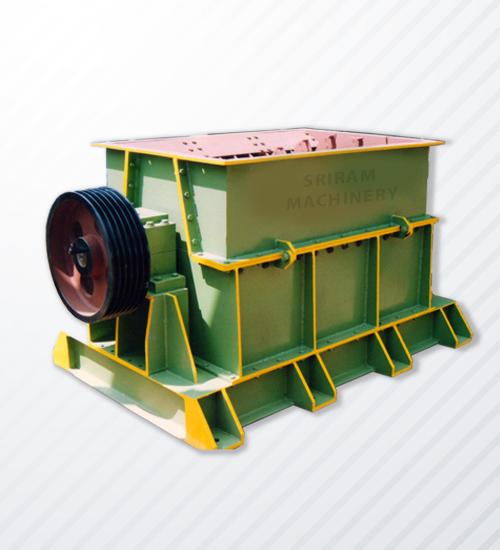

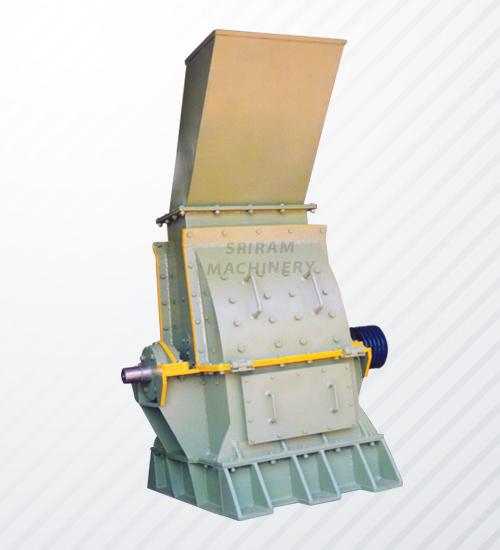

Roller Crusher

SRIRAM ROLLER CRUSHER is widely used for crushing friable materials which are ideally suitable for secondary or tertiary crushing. The principles of impact, compression, and shear are involved in this mill which produce uniform cubical output particles with minimum fines.

In Single Roller Crusher the rotation of roller carries the feed material into the crushing zone where the roller compress the feed lumps against stationary breaker plates . The clearance between the roller and breaker plate can be adjusted to get the desired output size of particles.

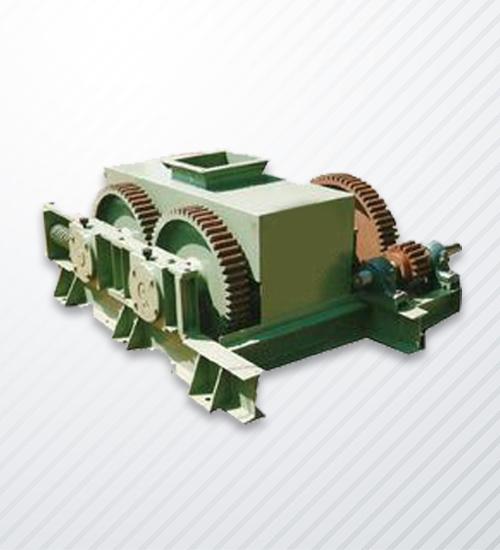

In Double Roller Crusher the feed material is passed through two rollers which rotate counter wise each other.The gap between the two rollers can be adjusted to achieve the desired product size.

Application Fields

Soft and Medium Hard Minerals.

Coal and Coke

Chemicals

Clay and Shell

Special Features

Rotor assembly is balanced statically and dynamically

Full set of shredder

hammers

Heavy-duty bearings mounted in housings with dust and lubricant seal

Fabricated steel housings with

continuous welds.

Housing split at the horizontal centerline for ease of maintenance.

Unique Design Permits exceptionally high throughput with minimum Power consumption and lower maintenance cost.

Technical Specifications

| Model | Roller Size (mm) | Power Reqd. (kw) 2 Nos. each |

Speed Speed (RPM) |

|

|---|---|---|---|---|

| Dia | Width | |||

| SRC-1 | 400 | 200 | 5.5 | |

| SRC-2 | 400 | 400 | 7.5 | |

| SRC-3 | 600 | 400 | 11.0 | |

| SRC-4 | 600 | 600 | 15.0 | |

| SRC-5 | 800 | 400 | 15.0 | |

| SRC-6 | 800 | 600 | 22.0 | |