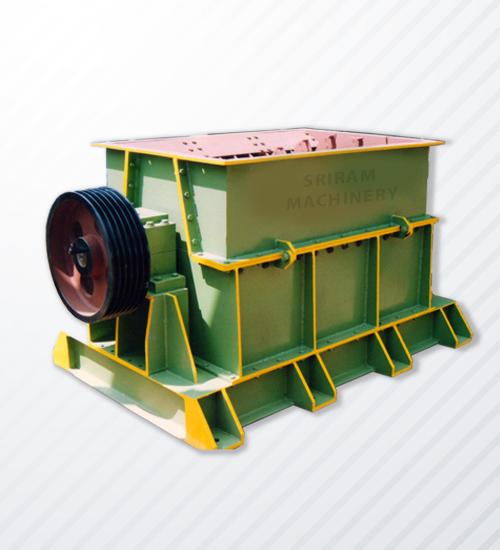

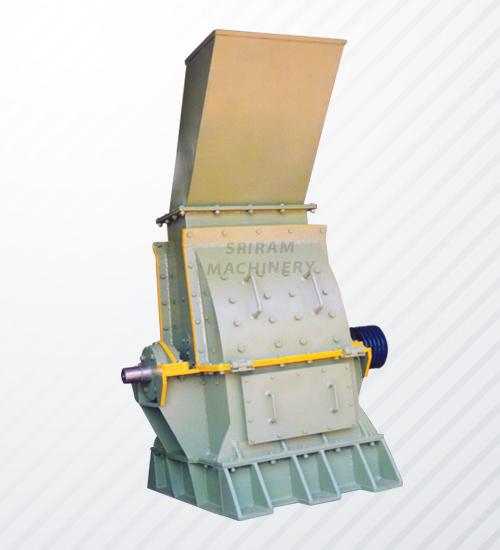

Jaw Crusher Lab Model

SRIRAM PULSE JET DUST COLLECTOR is an efficient system to control and collect the dust particles from the polluted air stream or Flue gas. The dust laden air is entering into the dust collector chamber due to section force created by a blower.

A set of filter bags arranged inside the chamber where the dust particles being filtered out on the outer surface of the bags and the clean air is sucked inside the bags and exhausted through Vent Pipe.

The fitered dust being removed by high-pressure jet of air that enters the top of the tubular filter bag. A pulse jet valve allows the pulse air through a blowpipe which constantly feeds the nozzle located above each bag. This will create a shock wave into the filter bag and due to this effect deposited dust particles dislodged from the bag surface and being collected through the hopper.

Application Fields

Coal

Minerals

Construction material

Chemicals

Boiler bed material

Spices

Special Features

Longer durability

Maintenance free

Completely balanced mounting base frame

Adjustable vibrating frequency

Simple way of changing screen frame

Technical Specifications

| Model | Size of Crusher | Power H.P Reqd. |

Max Feed Size |

Approximate Production in Tons/Hour with Jaw setting | |||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inches | 1/4" | 3/4" | 1" | 1.5" | 2" | |||

| SJC-6 | 250 X 150 | 10" X 6" | 7.5 HP | 3" | 1.0 | 2 | 3.5 | 4.5 | __ |

| SJC-7 | 300 X 175 | 12" X 7" | 10 HP | 6" | 2.5 | 6 | 9 | 12 | 18 |

| SJC-9 | 400 X 125 | 16" X 9" | 10-15 HP | 8" | __ | 10 | 13 | 15 | __ |

| SJC-12 | 600 X 300 | 24" X 12" | 20 HP | 10" | __ | 14 | 17 | 18 | __ |