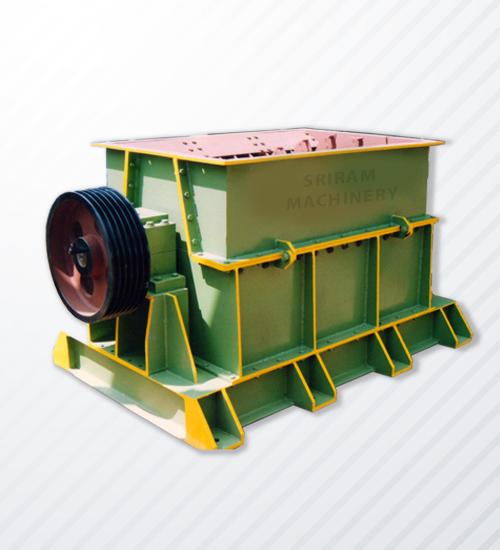

Hammer Crusher

SRIRAM HAMMER CRUSHER is specifically designed to suit for both secondary and tertiary size reduction applications.

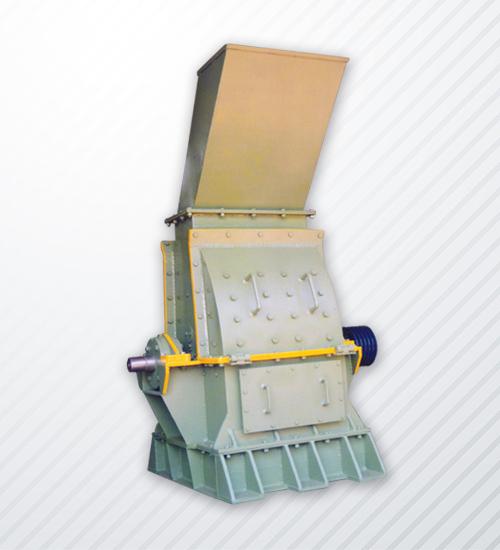

The concept of Impact, shear and attrition involved in this Mill which produces higher reduction ratio, more output with less power consumption.

The raw feed from the feed hopper enters into the crushing chamber where a set of revolving hammers impact the incoming feed material .The crushing takes place in between revolving hammers and the stationary breaker plates.

The required output size of the particle can be achieved either by adjusting the clearance between the breaker plate and hammer or by varying the opening size of the grate fixed at the discharge end.

Construction of Sriram Hammer Mills

- Base Frame is fabricated out of Heavy Mild Steel Plates fully reinforced with ribs.

- Breaker Liner plates of wear and tear resistance.

- Cage or Screen provided subject to type of Application, whether primary or secondary, which depends upon the type of material to be crushed.

- Rotor assembly consists of set of forged steel Hammers pivoted in the Rotor-Disc plates and the assembly is supported on both sides by Heavy Duty Spherical Roller Bearing Housings.

- Manholes and Inspection Doors are provided with the system for easy maintenance.

Special Features

High ratio of size reduction

High Degree of Uniform Cubical Particle size

Longer Durablility and Economical Operation

Wear Resitant Parts

Maintanance free system

High Throughput and less Power Consumption

Technical Specifications

| Model | Size (mm) | Power (HP) |

Speed (RPM) |

|

|---|---|---|---|---|

| Dia | Width | |||

| SHM-500 | 500 | 400 | 20-25 | 500-1000 |

| SHM-600 | 600 | 500 | 30-40 | 500-1000 |

| SHM-900 | 900 | 650 | 80-100 | 500-1000 |

| SHM-950 | 950 | 1200 | 125-130 | 500-1000 |

| SHM-1000 | 1000 | 1200 | 150-200 | 400-900 |

Note: All specifications noted above are approximate and subject to varied. This should be used as a guide only.