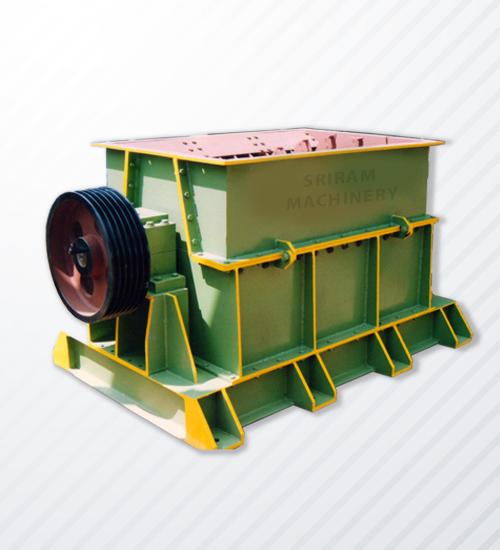

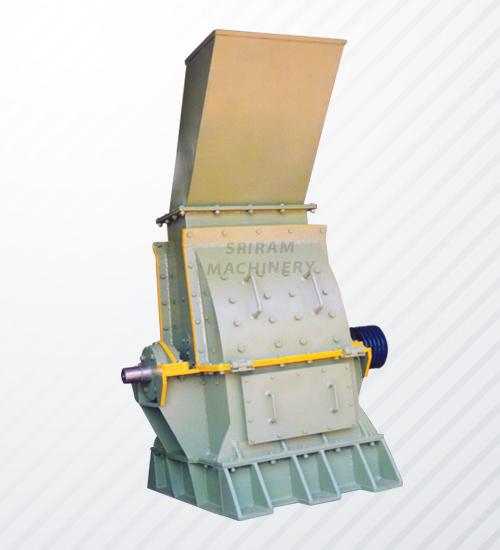

Impact Pulverizer

SRIRAM IMPACT PULVERIZER is widely used for Crushing & Grinding of various products to fine and ultra-fine particle sizes. It has an integral system of Grinding, classifying and separation process. The basic principles of Pulverizing Attrition, Friction, Shearing and Impact are combined in this mill to give maximum performance, capacity, particle fineness and grinding efficiency.

The material to be ground is conveyed from the Feed Hopper to the Grinding chamber by means of Automatic Rotary Feeder arrangement. A set of Hammer revolving at high velocity in the Grinding chamber reduces the lumps into fine powder.

The ground material is classified by Whizzer classifier and then pneumatically conveyed to Cyclone Separator through Impeller Fan. The un-size particles are rejected by Whizzer classifier and they are further subjected to strong Grinding. The impurities and tailings are automatically separated through side Door. The fine particles are separated from the air stream by Cyclone Separator for product discharge.

The air discharged by the Cyclone goes back into the Pulverizer, completing the cycle. The Dust collector attached with the system separates the Dust particles through Filter bags and maintains Dust-free operation.

Special Features

Crushing, Grinding and classifying at single stage

Steep fine particle recovery rates

Economical operation

Easy to clean & maintenance

Closed circuit system & Dust-free operation

Construction & options

- The system chiefly consists of Grinding Chamber, Feed Hopper, Rotary Feeder, Whizzer Classifier, 1.D. Fan, Automatic feeding mechanism, Cyclone Separator and Dust Collector.

- Option of Double-Whizzer Classifier system for producing powder in the Ultra-fine Range.

- Option of water coolling system for the grinding chamber

Application Fields

All non-metallic minerals

Lime stone, Calcite, Dolomite, Rock phosphate, Apatite, Chromite, Ilmenite, Gypsum, China Clay, Fire clay, Feldsper, Baryte, Bentonite, Mica, Magnesite, Coal, Coke, Lignite, Charcoal, etc.

Food Products

Turmeric, Chillies, Spices, Cereals & Wheat, Dry Rice, Corn, Tapioca Chips, etc.

Others

Herbals, Chemicals, Pharmaceuticals, Cattle & Poultry Feeds, Cosmetics, Dyes & Intermediates, Paints, Resins, Wood Chips, Coconut Shell, etc.

Technical Specifications

| Model | Chamber Dia (inches) |

Power Reqd. (HP) |

Rotor Speed (RPM) |

Space Reqd. (Feet) |

|---|---|---|---|---|

| SRM-15 | 15 | 15 | 3000 | 8'x8'x12' |

| SRM-18 | 18 | 15 | 2800 | 8'x8'x12' |

| SRM-22 | 22 | 20-25 | 2700 | 10'x10'x15' |

| SRM-25 | 25 | 30 | 2500 | 12'x12'x16' |

| SRM-28 | 28 | 30 | 2300 | 14'x14'x16' |

| SRM-30 | 30 | 40 | 2200 | 16'x16'x18' |

| SRM-32 | 32 | 40-50 | 2100 | 16'x16'x18' |

| SRM-34 | 34 | 50-60 | 1950 | 16'x16'x18' |

| SRM-42 | 42 | 90 | 1800 | 8'x8'x12' |