Ball Mill

SRIRAM BALL MILL is chiefly applied for grinding of various products to fine and ultra fine particle sizes. This can be utilized for both wet grinding as well as dry grinding applications.

BATCH MILL consists of a cylindrical steel shell with flanged steel heads, rotating on a horizontal axis. Both the ends of the mill are strongly designed to withstand the rotational load of the feed material, grinding media and the mill itself.

Openings are provided through which the grinding media and process material can be loaded and discharged. The discharge opening is often in the opposite side of loading manhole. The mill driven by motor coupled to the Reduction Gear Box.

In CONTINUOUS MILL, the raw feed material is at controlled rate enters into the inlet end of the mill. The fines are discharged through the outlet end of the mill by a Blower to the cyclone separator.

Mill Liners are provided to restrict wear and tear of the Shell Inner Chamber. The grinding media balls or pebbles and feed material which collide with each other due to rotary motion of the cylindrical shell and thus the fines are generated under the force of Impact and Collision.

Application Fields

Non metallic Minerals

coal

Coke

Clay

Industrial slag

Dyes & Pigments

Dry and wet waste grinding

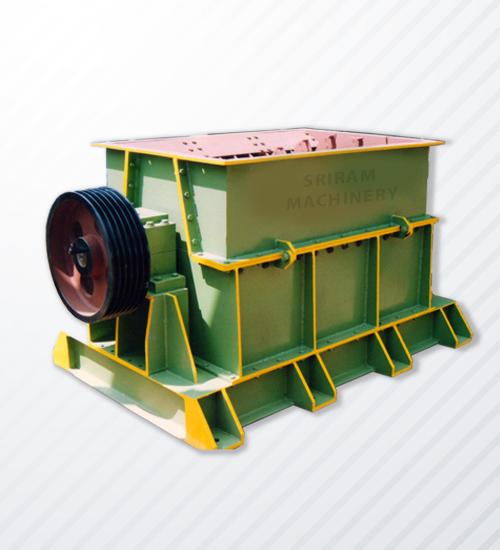

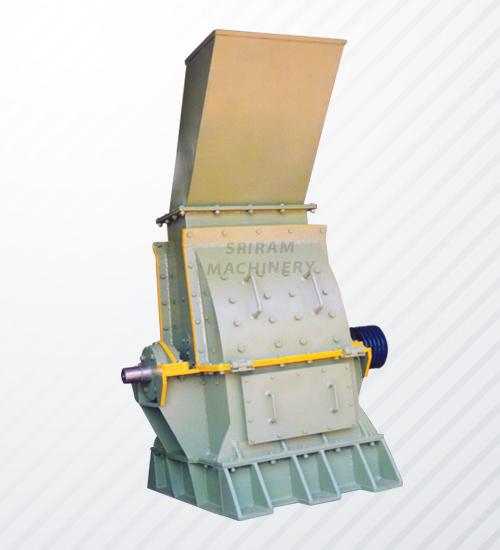

Special Features

Main frame is fabricated out

of heavy Mild Steel

High grade Manganese steel Jaw plates&

Jaw Plates of Wear & Tear Resistant

Double-Fly wheel

system

Higher Shock-absorbing

capability

Single Toggle mechanism with excellent Load bearing system

Longer Durability, Reliability & Maintenance free system.

Batch Type Mills

| Mill Size | Container Capacity | Motor HP |

|---|---|---|

| 20" X 20" | 100 ltrs | 2HP |

| 2' X 2' | 175 ltrs | 3HP |

| 2'-6" X 2'-6" | 325 ltrs | 5HP |

| 2'-6" X 3'-6" | 440 ltrs | 7.5HP |

| 3' X 3' | 590 ltrs | 7.5HP |

| 3'-6" X 3'-6" | 990 ltrs | 10HP |

| 4' X 4' | 1400 ltrs | 15HP |

| 4'-6" X 4'-6" | 1600 ltrs | 20HP |

Ball Mills are fabricated from Mild Steel, Rubber lined and Stainless Steel.

Note Working capacity to be calculated at 50% of the container capacity

Continuous Discharge Mills

| Mill Size (mm) |

Drive Motor HP |

Fan Motor HP |

Production Capacity (Kgs/Hr) |

|---|---|---|---|

| 1200 X 1200 | 15 | 5 | 250 - 500 |

| 1300 X 2500 | 30 | 5 - 10 | 700 - 1200 |

| 1500 X 3000 | 50 | 15 - 20 | 1000 - 2000 |

| 1800 X 5000 | 100 | 20 - 30 | 2000 - 3000 |

| 2000 X 6000 | 150 | 30 - 40 | 3000 - 5000 |

Production capacity, size and Motor HP subject to vary which depends on physical properties and particle size of feed materials.

The above figures are for guidance only and tends to vary.