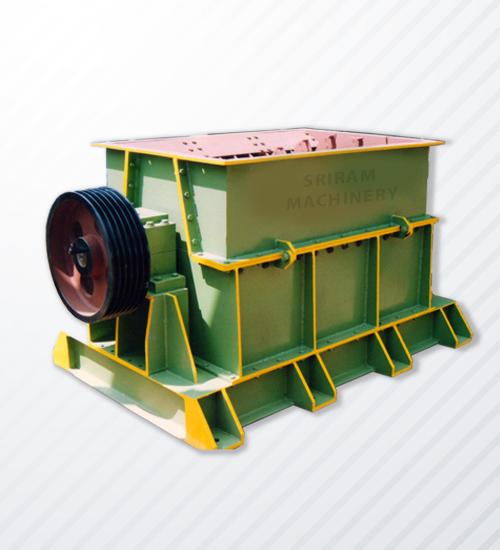

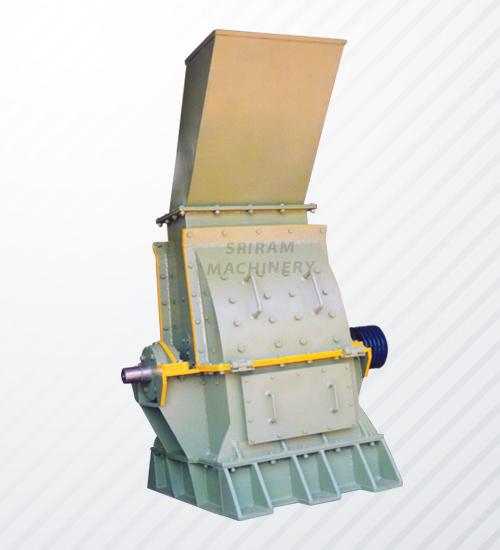

Jaw Crusher

SRIRAM JAW CRUSHER is designed for primary crushing of various hard and abrasive minerals with minimum rubbing action.

It is constructed with single toggle mechanism having swing Jaw mounted directly on the Eccentric shaft . The forward and downward motion of movable jaw plate forces the feed particle to disintegrate in a uniform manner.

The lower end of the swing jaw is being pivoted against the Toggle plate by a spring hold tension rod which absorbs the shock created by the eccentricity motion of the Jaw.

The setting of the outlet opening of the Jaw crusher can be adjusted to achieve the desired product size with uniform outflow

Application Fields

Minerals

Coal

Coke

Lignite

Industrial Slag

Gypsum

Construction Debris

Special Features

High Grade Alloy Steel

Jaw Plates

Double Fly Wheel

attachment

Single Toggle Mechanism with Excellent Load Bearing system

Higher Shock absorbing Capability

Higher Output withLess Power Consumption

Durabilty and Maintenance free system

Technical Specifications

| Model | Size of Crusher | Power H.P Reqd. |

Max Feed Size |

Approximate Production in Tons/Hour with Jaw setting | |||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inches | 1/4" | 3/4" | 1" | 1.5" | 2" | |||

| SJC-6 | 250 X 150 | 10" X 6" | 7.5 HP | 3" | 1.0 | 2 | 3.5 | 4.5 | __ |

| SJC-7 | 300 X 175 | 12" X 7" | 10 HP | 6" | 2.5 | 6 | 9 | 12 | 18 |

| SJC-9 | 400 X 125 | 16" X 9" | 10-15 HP | 8" | __ | 10 | 13 | 15 | __ |

| SJC-12 | 600 X 300 | 24" X 12" | 20 HP | 10" | __ | 14 | 17 | 18 | __ |

* These are representative capacities only and subject to change. This should be used as guide only.